Amylopectin

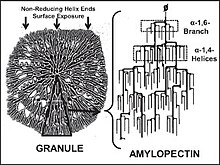

Amylopectin /ˌæmɪloʊˈpɛktɪn/ is a water-insoluble[1][2] polysaccharide and highly branched polymer of α-glucose units found in plants.

Humans and other animals that eat plant foods also use amylase, an enzyme that assists in breaking down amylopectin, to initiate the hydrolysis of starch.

Its inner chains are formed of 20–24 glucose subunits.Dissolved amylopectin starch has a lower tendency of retrogradation (a partial recrystallization after cooking—a part of the staling process) during storage and cooling.

[7] Composed of α-glucose, it is formed in plants as a primary measure of energy storage in tandem with this structural metric.

Finally, in general, the more densely packed the resulting molecule of amylopectin, the higher the strength of the starch gel as a whole unit.

[14][16] This gave rise to the Meyer definition of amylose and "reserv[ing] the name amylopectin to carbohydrates that are branched molecule, degraded by b-amylase only to the stage of residual dextrin".

The major sources of amylopectin of starch intake worldwide are the cereals such as rice, wheat, and maize, and the root vegetables potatoes and cassava.

[25] Upon cooking, amylopectin in the starch is transformed into readily accessible glucose chains with very different nutritional and functional properties.

[26] During cooking with high heat, sugars released from amylopectin can react with amino acids via the Maillard reaction, forming advanced glycation end-products (AGEs), contributing aromas, flavors and texture to foods.

Amylopectin is also sometimes used as a workout supplement due to this caloric density and a correlation with muscle protein synthesis.

Amylopectin has also been widely used for the development of edible coating films because of its abundance, cost-effectiveness, and excellent film-forming abilities.

[32] This stiffening effect is used for several textile industry processes, such as printing and pressing, to maintain the shape of a fabric over time.

Amylopectin is also used as a sizing agent for yarns, to reinforce and protects the fibers from abrasion and breakage during weaving.

Principles relating to route of administration, metabolism, site of specific targeting, and toxicity are most important within this field.

These structures aim to keep the drug intact until its site of action and release it at a correct dosage when exposed to a specific marker.

[38] Native starch can also be modified in physical, chemical, and enzymatic ways to improve mechanical or biochemical properties.

Amylopectin-based fibers have been fabricated mainly by blending native or modified starches with polymers, plasticizers, cross-linkers, or other additives.

Natural bone is a complex composite material composed of an extracellular matrix of mineralized fibers containing living cells and bioactive molecules.

Consequently, the use of fibers in biomaterial-based scaffolds offers a wide variety of opportunities to replicate the functional performance of bone.

[40] In the last decade, fiber-based techniques such as weaving, knitting, braiding, as well as electrospinning, and direct writing have emerged as promising platforms for making 3D tissue constructs.

Bionanocomposites have been used in tissue engineering to replace, support, or regenerate the cells, organs, or parts of human entity such that it can function as normal.

[42] In conjunction with other nanomaterials like cellulose nanocrystals, nano-ZnO, nanoclay, biodegradable synthetic polymers, starch is one of the most popular materials for the preparation of bionanocomposites for various biomedical applications such as controlled drug release, scaffold for tissue engineering, and cement for bone regeneration.

This allows for starch to withstand the higher fluid flow and mechanical forces prevalent in bone, cardiac, and endothelial tissue.